AI In Manufacturing

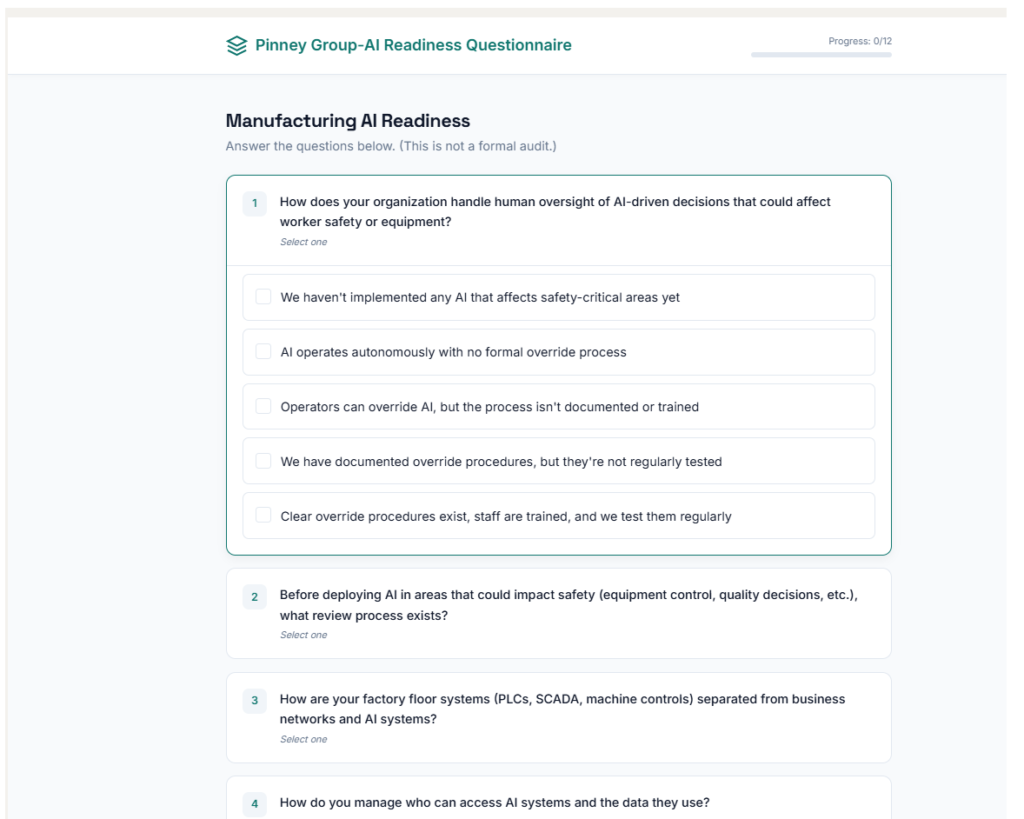

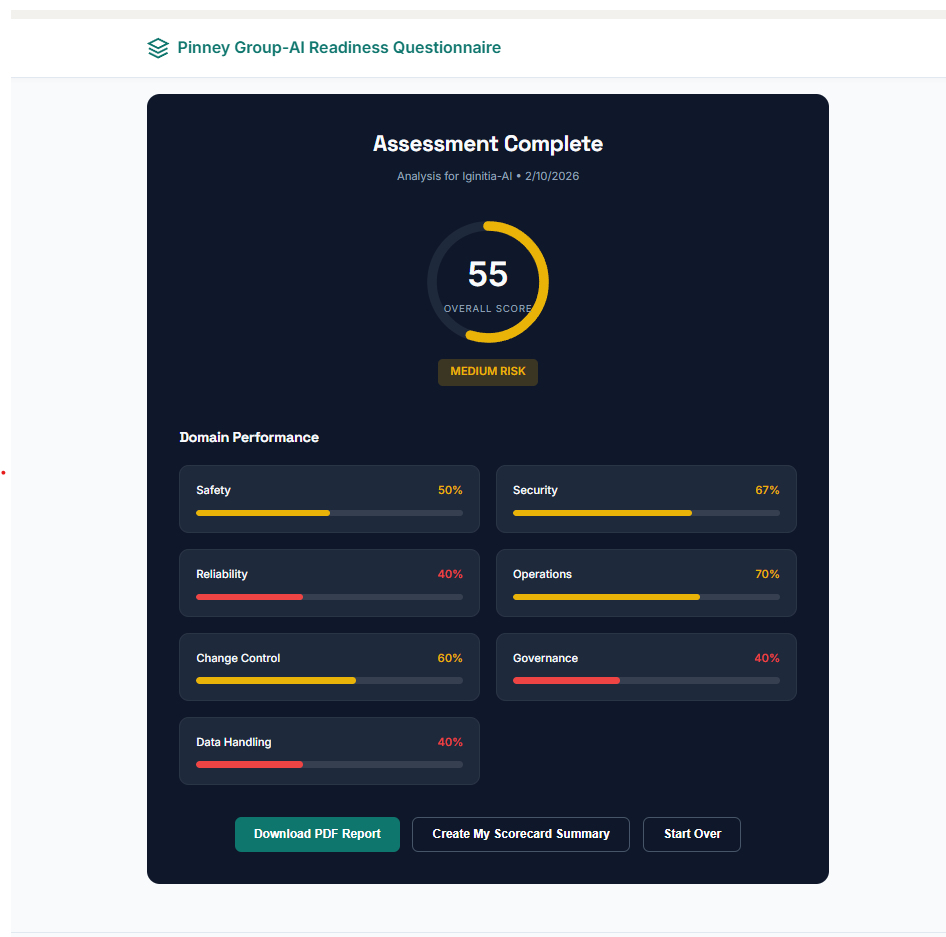

AI Readiness Questionnaire

This AI Readiness Questionnaire is a structured diagnostic tool designed to help organizations quickly assess how prepared they are to adopt, scale, and govern AI responsibly. Through a guided set of practical, business-focused questions spanning data, security, operations, governance, and workforce readiness, it evaluates both technical foundations and organizational maturity. The platform converts responses into an executive-level scorecard with domain benchmarks, risk indicators, and prioritized next steps, giving leadership a clear view of where they stand today and what actions will drive the most immediate impact. The result is a concise, actionable roadmap that helps companies move forward with AI confidently, safely, and aligned to real business outcomes rather than hype.

Our Work

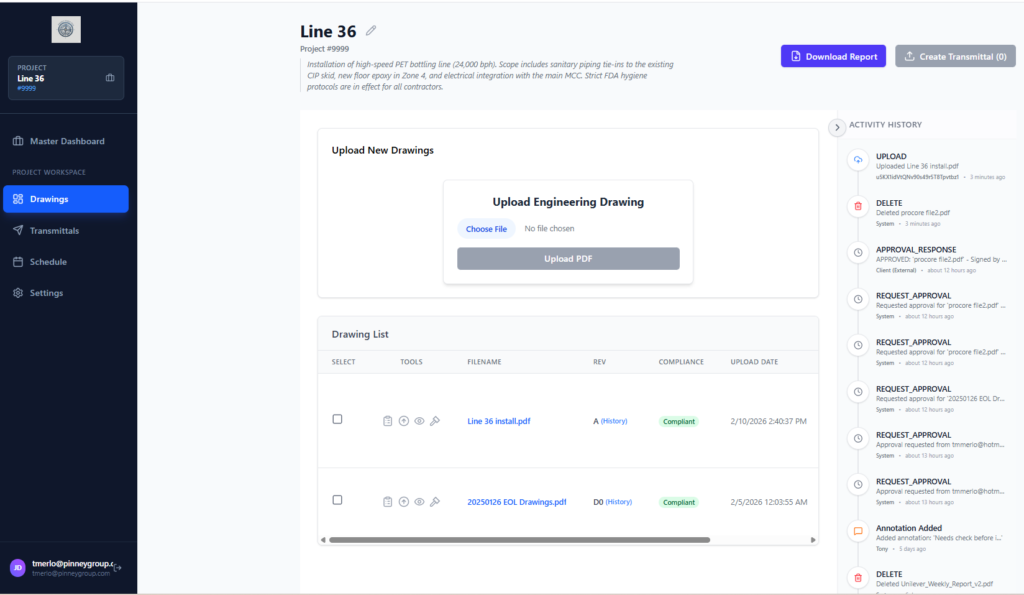

Project North Star

Project North Star is an AI-powered engineering workspace platform designed to replace complex, expensive tools like Procore and MS Project with a streamlined solution that adapts to your team’s existing workflows, not the other way around. The platform intelligently reads, indexes, and connects engineering drawings and specifications, automatically detecting conflicts and tracking revisions across projects. With built-in transmittal management for timestamped document delivery proof, automated submittal logs, RFI drafting assistance, and lightweight project scheduling, North Star eliminates the friction of traditional construction management software while providing the documentation accountability that engineering teams need. Built for firms that have spent decades refining their processes, it’s the anti-complexity alternative that enhances rather than disrupts how you already work.

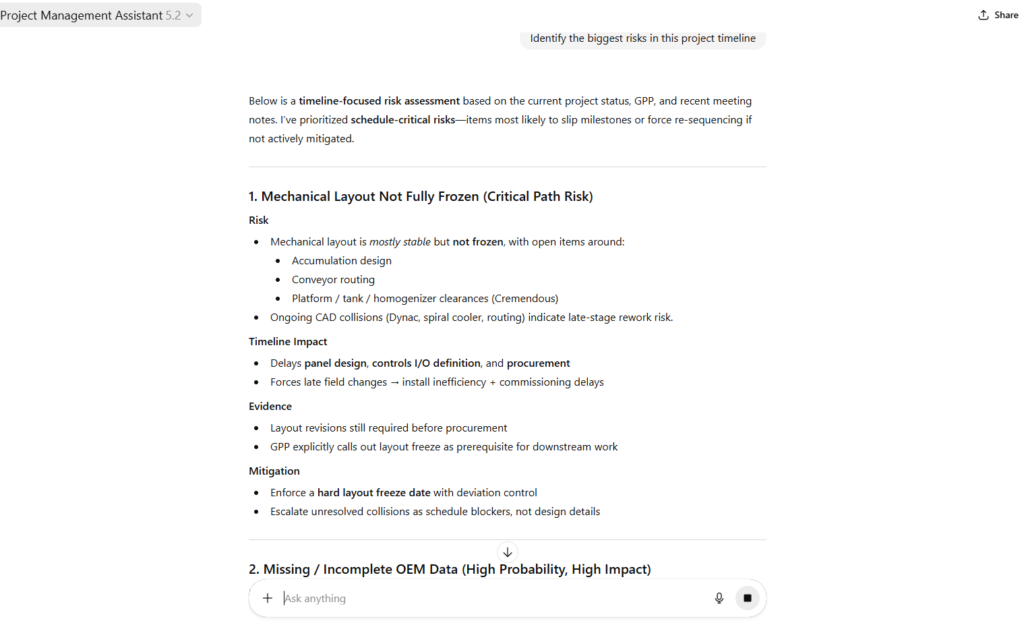

Project Management Asst.

Project Management Assistant is an AI co-pilot built for food and beverage manufacturing projects. It analyzes real project documents, standards, meeting notes, and live timelines to identify schedule risks, integration gaps, and execution bottlenecks and then translates them into clear, actionable guidance. Designed for senior project managers and engineers, it supports layout freeze decisions, long-lead procurement planning, controls and electrical alignment, commissioning readiness, and stakeholder communication. The result is faster decisions, fewer late surprises, and tighter control of complex, multi-vendor manufacturing initiatives.

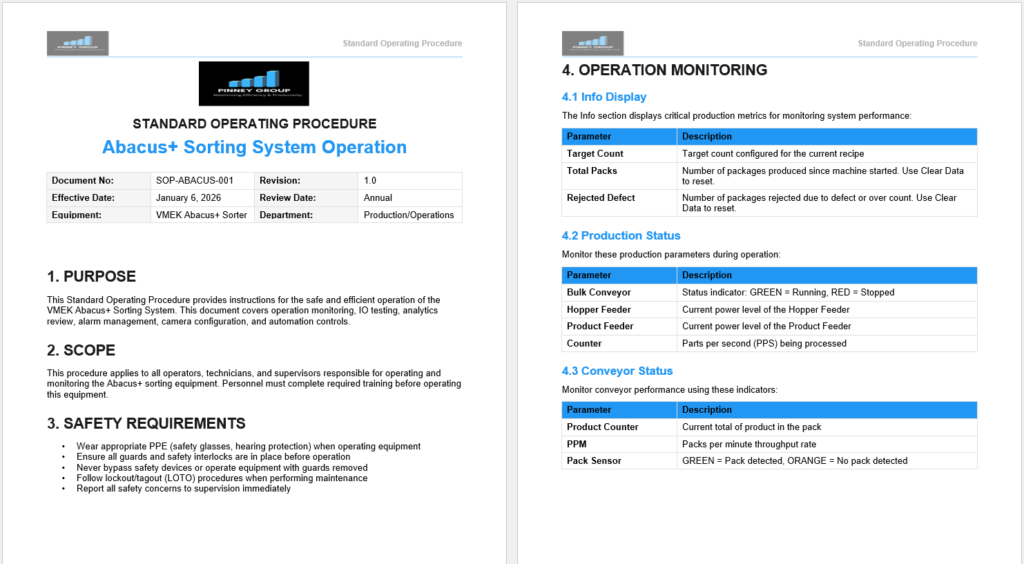

SOP Creation Tool

SOP Creation Tool is a purpose-built AI assistant designed to help manufacturers rapidly create clear, operator-friendly One Point Lessons (OPLs) by turning tribal knowledge, equipment details, and stakeholder input into standardized, easy-to-use visual instructions. It guides teams through best practices for capturing the right level of detail, aligning operations, maintenance, and engineering stakeholders, and organizing OPLs so they are intuitive on the plant floor. The result is faster buy-in, more consistent execution, reduced training variability, and fewer mistakes at the point of work, especially on complex equipment like fillers, conveyors, and support systems such as stack lights and material handling indicators

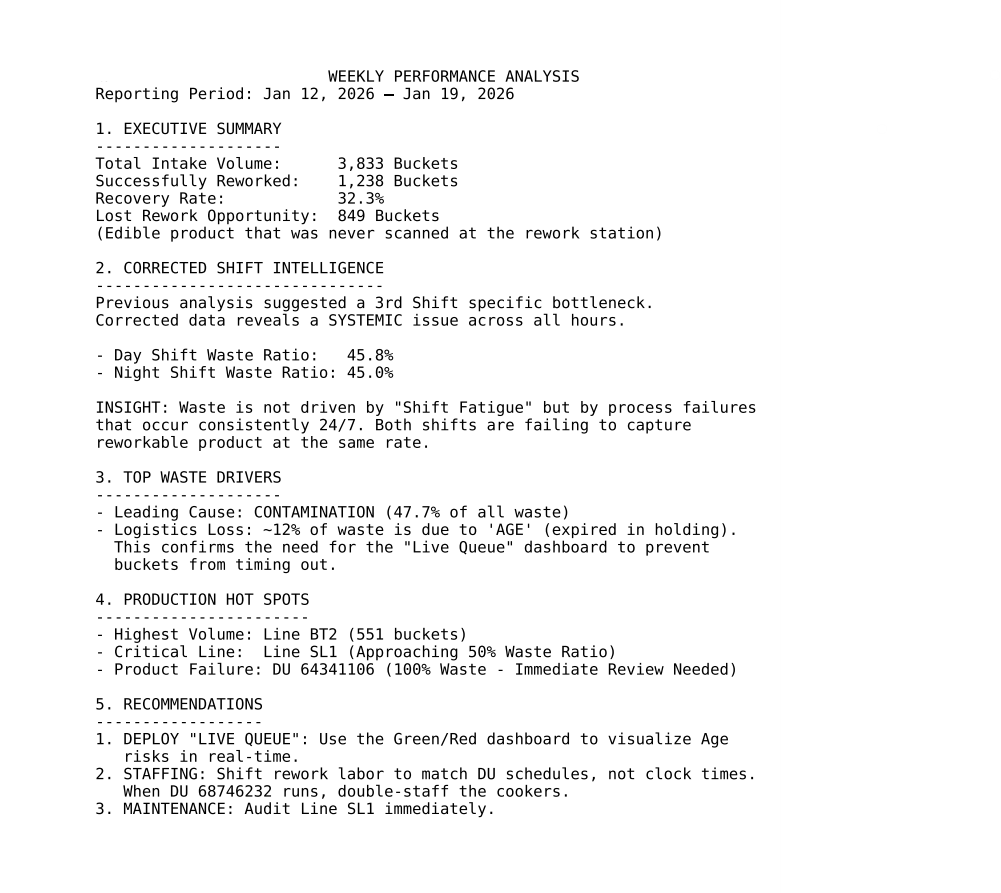

Waste Tracking Tool

Waste Tracking Tool This tool is a flexible, shop-floor-ready tracking platform designed to capture, standardize, and analyze virtually any event in a manufacturing environment. While often deployed for waste, it is intentionally built to handle anything that needs to be measured or explained on the line: production losses, quality holds, rework, downtime, material movement, changeovers, sanitation events, safety incidents, or custom operational KPIs. Operators interact through fast, scan-based or touch-friendly workflows, while supervisors and engineers get structured, time-stamped data that is immediately usable for reporting, root-cause analysis, and continuous improvement. The result is a single, adaptable system that turns everyday manufacturing activity into reliable data, without forcing the plant to change how it actually runs.

Maintenance Support Agent

Maintenance Support Agent is an AI-powered assistant designed specifically for manufacturing environments, helping operators, technicians, and maintenance teams quickly understand, operate, and troubleshoot complex equipment using official machine documentation and orientation manuals. It provides clear, role-appropriate guidance on machine operation, safety devices, sensors, HMI screens, alarms, sequences of operation, and common issues with the goal of reducing downtime, improving safety, and standardizing knowledge across shifts. By giving workers instant, reliable answers drawn only from approved documentation, this GPT helps manufacturing companies preserve tribal knowledge, speed up training, support maintenance teams, and keep production running efficiently without relying on guesswork or external resources.

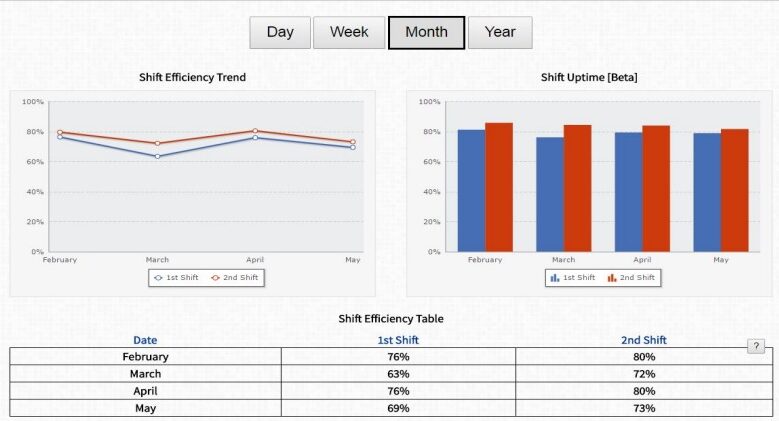

Downtime Tracking Systems

If you’re tracking downtime manually, let the Pinney Group do the work for you. We can provide real-time data and reporting that can help your company reduce downtime, increase efficiency and meet production goals. Know whether your lines are running, how efficiently and exactly how to reduce production downtime. This will provide you with real time data that will track your production line efficiency in real-time and analyze trends according to shift, line or even SKU.

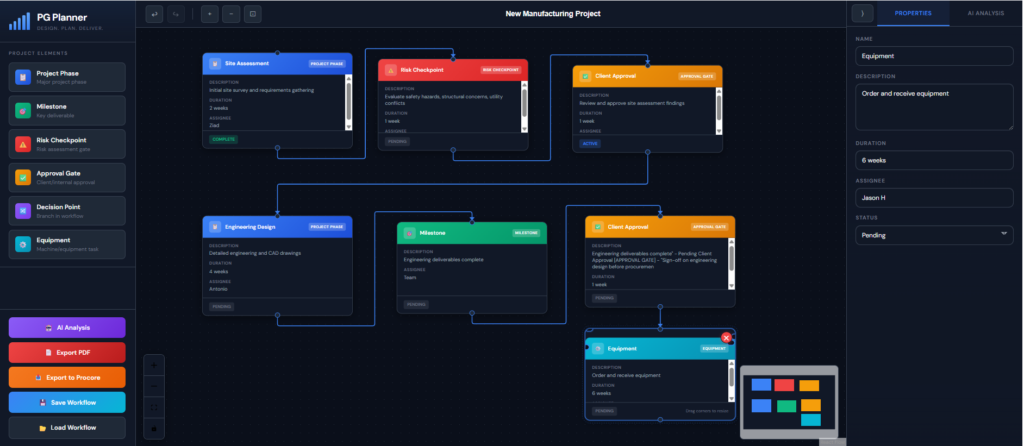

PG Planning Tool

PG Planner is a visual project workflow designer built for manufacturing and engineering teams to map out complex projects from site assessment through commissioning. Drag and drop project phases, milestones, risk checkpoints, approval gates, decision points, and equipment tasks onto an interactive canvas, then connect them to define dependencies and sequencing. The built-in AI Analysis feature reviews your workflow and provides coaching feedback on missing steps, risk gaps, and scheduling concerns based on manufacturing best practices. When your plan is ready, export it as a PDF for client presentations or push it directly to Procore to create your project structure automatically. Whether you’re planning an equipment relocation, production line installation, or facility upgrade, PG Planner helps engineering teams design, plan, and deliver with confidence.

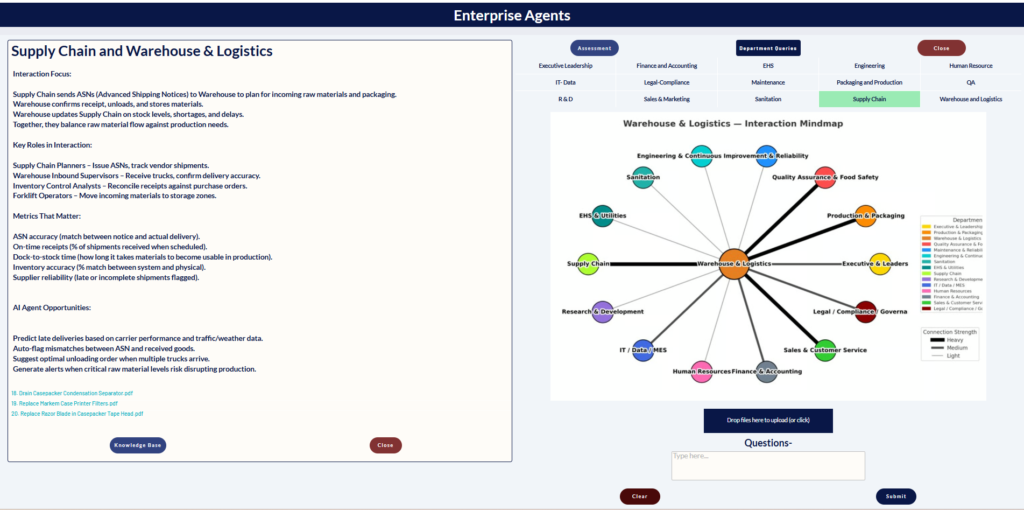

Enterprise Agents

Enterprise Agents is an AI-powered organizational intelligence platform that maps and analyzes the complex interactions between departments across your enterprise. By visualizing how functions like Supply Chain, Warehouse & Logistics, Production, Quality Assurance, and Engineering interconnect, the platform identifies key roles, tracks critical metrics (like ASN accuracy, dock-to-stock time, and inventory accuracy), and surfaces AI agent opportunities such as predicting late deliveries based on carrier performance and weather data, auto-flagging mismatches between shipping notices and received goods, or generating alerts when raw material levels risk disrupting production. With an integrated knowledge base linking to relevant SOPs and procedures, Enterprise Agents helps organizations understand cross-functional dependencies and deploy targeted AI solutions that improve operational efficiency across the entire value chain.